Dry process for MPC polymer coating.

Home![]() Reserch

Reserch![]() Plasma and VUV Processing

Plasma and VUV Processing

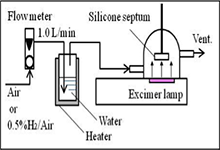

●Development of dry coating process by 172 nm vacuum ultra violet.

Dry process for MPC polymer coating.

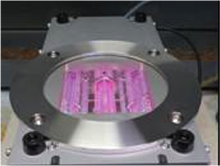

172 nm VUV (Excimer lamp)

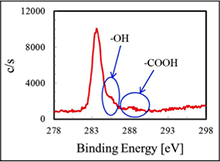

Modification of silicon surface by VUV irradiation.

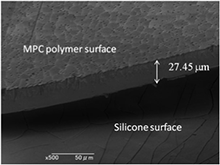

Coated MPC polymer on silicone rubber surface.

Silicone rubber has been widely used in medical devices, in particular, those in contact with blood and the vasculature due to its specific mechanical properties (compliance, softness) and relatively good blood compatibility. Nevertheless, many studies have indicated that blood contact with silicone can lead to the formation of thrombi and emboli and so in low shear environments its use is generally limited to short term blood contact.

The 2-methacryloyloxyethyl phosphorylcholine (MPC) polymers are recognized as the effectively material reducing blood adsorption. Therefore, simple and durable coating techniques of MPC polymer to the surface of silicone rubber are desired.

The aim of this research is to develop advanced dry coating process. A 172 nm ultra vacuum violet (VUV) has been employed to modify the surface of silicon rubber. The VUV has some advantages, for example, it can easily irradiate to complicated configuration. Effect of irradiation time and concentration of MPC polymer in a solvent on the membrane formation was investigated. Ability of the endurance of the membrane was investigated by leaching tests in a physiological salt solution.